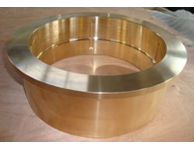

Bronze

Phosphorus Bronze - IS 28

The standard uses for this metal is for Heavy Duty Gears, High Load Bearings, Bushes, Worm Wheels, (which requires good shock resistance), Automotive Bushings, Bearings, and Synchronizing Rings. For higher strength, we can add Tin and Nickel for high performance and longer life.Tin Bronze - IS 306

This metal is generally used in Marine Pumps, Valves, Bearings, Bushes, Seal Rings, Piston Rings, Seal Fitting and Gears.

Leaded Bronze - IS 318, BS 1458

The Components produced from this metal are used for high speed and heavy Pressure Pump Parts, Bushes, Split Brass and Turbocharger Bearings for moderate's loads; anti-seizing conforms to shaft irregularities and pressure tight castings. Also this metal specifies the requirements for Railway Bronze Casting, Bushes and Split Brass under than five classifications based on the use to which the material is put.

Aluminum Bronze - IS 305

There are generally two types of grade for this metal, AB1 and AB2. Both have excellent resistance to Corrosion and Oxidation and wear by sea water due to their superior mechanical properties. These alloys are anti-fouling self water corrosion resistant parts, and are generally used in Marine hardware components for Pumps, Fluid Control Valve, deck and underwater fittings Propellers, Gear Blanks, deep drawing Dies, non-sparking tools, Pickling Equipment and Worm Wheels.

Manganese Bronze - IS 304

The Components produced from this metal are used for extra heavy duty high strength alloy for large Valve Stems, Gears, Cams, slow speed heavy load Bearings, Screw Down Nuts, and Hydraulic Cylinder Parts.

Silicon Bronze - IS 1028

Silicon Bronze parts are used in Sewage Disposal Equipment, Chemical Process Equipment, Marine Hardware and Anti-Corrosive Pipe Fittings, such as valves and pumps. Silicon Bronze may also provide a good substitute for Tin and Tin Zinc Bronzes.